In the realm of electronics, the ability to generate a series of harmonically related frequencies is crucial for various applications. Enter the comb generator, an unsung hero of the electronics world. Named for the ‘comb-like’ appearance of its output spectrum, a comb generator produces a vast array of evenly spaced frequency components, much like the teeth of a comb.

At its core, a comb generator is a device that takes a single frequency input and multiplies it to produce numerous harmonics or frequency components. While it may sound simplistic, the underlying mechanics are steeped in intricate electronic principles. The resulting spectrum from a comb generator can span a broad range, from low radio frequencies to high microwave frequencies.

To truly appreciate its significance, it’s essential to understand its diverse applications, from calibrating high-frequency measurement equipment to acting as a reference in communication systems. As we delve deeper into this article, you’ll unravel the many layers of the comb generator, from its inner workings to its multifaceted applications in the modern electronics landscape.

Contents

Basic Working Principle

The comb generator’s primary function is to produce a spectrum of harmonically related frequencies, but how does it achieve this feat? Let’s break down the basic mechanics:

- Input Signal: Everything starts with an input, typically a sinusoidal waveform or pulse. This signal is fed into the comb generator to be manipulated and transformed.

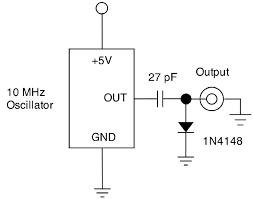

- Nonlinear Process: The magic happens here. When the input signal passes through a nonlinear device, like a diode or transistor, it generates harmonics. These harmonics are integer multiples of the original input frequency. For instance, if the input is 10 MHz, the harmonics produced might be at 20 MHz, 30 MHz, and so on.

- Filtering: Not all harmonics are useful or desired. Sometimes, certain harmonics need to be attenuated or enhanced. Filtering circuits come into play, refining the output to meet specific needs.

- Output Spectrum: The resulting output, after processing and filtering, is a series of peaks (or “teeth”) at regular frequency intervals, reminiscent of a comb’s appearance. The spacing between these peaks is equal to the fundamental or input frequency.

- Repetition Rate: In the case where pulsed signals are used, the repetition rate of the pulses determines the spacing between the comb’s teeth. The higher the repetition rate, the closer the teeth are in frequency.

To visualize the working principle, imagine a stone thrown into a calm pond. The stone’s impact generates a series of ripples spreading outward. In the world of comb generators, the stone is our input signal, and the ripples are the harmonics. By controlling the size and shape of the stone, and the pond’s characteristics, we can influence the ripple pattern, akin to the comb generator manipulating the input signal to create a desired harmonic spectrum.

In essence, the comb generator leverages the natural tendencies of electronic components, pushing them to produce a plethora of frequencies from a single, simple input. This foundational principle is what enables its vast array of applications across the electronics domain.

Types and Variations of Comb Generators

The versatility of comb generators is highlighted by the various types and adaptations crafted to cater to specific applications and requirements. Let’s explore the main categories:

- Pulse-Driven Comb Generators: These generators utilize a pulse waveform as their primary input. The sharp transitions of the pulse create a broad spectrum of harmonics. By adjusting the pulse width and repetition rate, one can control the harmonic content and spacing.

- Sinusoidal-Driven Comb Generators: With a sinusoidal waveform as an input, these generators typically use nonlinear components, like diodes, to produce harmonics. The resulting comb spectrum is cleaner but may not be as broad as that produced by pulse-driven types.

- Step Recovery Diode (SRD) Comb Generators: SRDs are specially designed diodes that can abruptly cease current flow, creating sharp transitions. When driven with a sinusoidal signal, SRDs produce a rich harmonic content, making them ideal for high-frequency applications.

- Nonlinear Transmission Line (NLTL) Comb Generators: These use a transmission line imbued with nonlinear capacitance to produce a comb spectrum. NLTL generators can offer ultra-wideband performance, spanning from low frequencies to several tens of gigahertz.

- Optical Comb Generators: In the realm of photonics, optical comb generators use ultrafast laser pulses to create a comb spectrum in the optical frequency domain. These are essential for high-precision spectroscopy and optical communications.

- Microresonator-based Comb Generators: Harnessing microfabrication technology, these generators utilize tiny optical resonators to produce comb spectra. They have garnered attention for their compact size and potential integration with electronic circuits.

- Active Feedback Comb Generators: By employing active feedback mechanisms, these generators stabilize and refine the comb’s teeth, ensuring precision and consistency, which is critical in applications like metrology and frequency synthesis.

Each type of comb generator has its own set of advantages, limitations, and ideal use-cases. The choice of which to use depends on factors like required bandwidth, frequency stability, physical size constraints, and power consumption.

The ongoing evolution in electronics and photonics ensures that comb generator technology continues to adapt and innovate, offering solutions tailored to an ever-expanding array of challenges and applications.

Challenges and Limitations

While comb generators are essential tools in the electronics arena, they come with their set of challenges and limitations. Understanding these factors is crucial for ensuring effective utilization and achieving desired results. Here’s a look at some prevalent challenges:

- Spectral Purity: Comb generators can sometimes produce unwanted spurious signals or noise in addition to the desired harmonics. This can be problematic, especially in precision applications where a clean spectral output is mandatory.

- Harmonic Attenuation: As you move further away from the fundamental frequency, the amplitude of the harmonics typically decreases. This natural attenuation might render higher harmonics unusable in certain applications.

- Linearity Constraints: Nonlinear components, like diodes, which are vital for generating harmonics, can introduce distortions if driven beyond their linear operating range.

- Thermal Considerations: Comb generators, especially when operated at high power levels, can produce significant heat. Without adequate thermal management, this can affect performance or even damage the device.

- Bandwidth Limitations: While some comb generators can produce a broad spectrum, there are limits to how wide this spectrum can be, especially while maintaining consistent harmonic spacing and amplitude.

- Physical Size and Integration: In applications requiring miniaturized electronics, like in certain communication devices, the size of the comb generator might pose integration challenges.

- Power Consumption: High-performance comb generators, particularly those delivering broad spectral content, can be power-hungry, posing challenges in portable or battery-operated applications.

- Cost Implications: Advanced comb generators, especially those catering to niche applications or requiring high precision, can be expensive to produce and procure.

- Calibration and Maintenance: Over time, the performance of a comb generator can drift, necessitating regular calibration. Maintenance can also be a concern, especially in environments with temperature fluctuations, vibration, or other external factors.

Awareness of these challenges enables engineers and researchers to make informed decisions, develop workarounds, and continue the pursuit of innovations to enhance comb generator performance. As technology progresses, many of these limitations are being addressed, paving the way for more efficient, versatile, and robust comb generator solutions.

References:

Leave a Reply