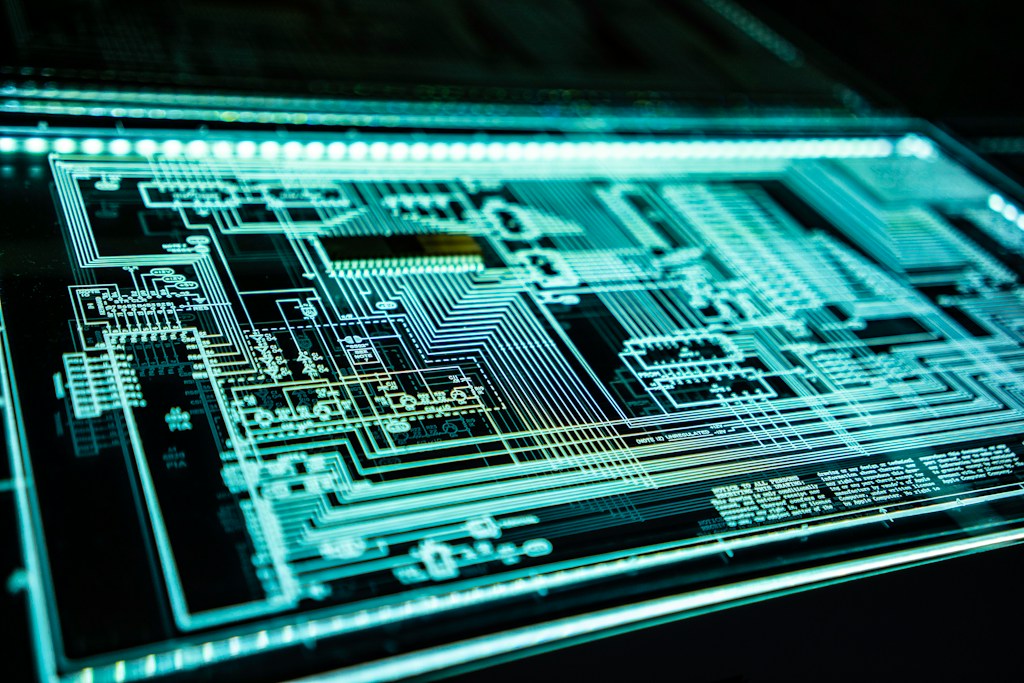

Electronic design and manufacturing (https://conclusive.tech/) form the backbone of our modern technological world. From smartphones to satellites, these processes are integral in shaping the devices and systems that define our daily lives. This analysis delves into the intricate world of electronic design and manufacturing, highlighting its evolution, key components, challenges, and future trends. Understanding these elements is crucial, as they not only drive technological advancement but also pose unique challenges in a rapidly evolving digital landscape.

Contents

History and Evolution

The journey of electronic design and manufacturing began in the early 20th century, marked by rudimentary designs and manual assembly processes. Initially, the focus was on basic electronic components like resistors and capacitors, evolving into more complex circuits with the advent of transistors in the mid-20th century.

The introduction of integrated circuits (ICs) in the 1960s revolutionized the industry, allowing for more compact and efficient designs. This era witnessed the transition from hand-drawn schematics to computer-aided design (CAD), enabling more precise and intricate electronic designs. The manufacturing processes also evolved, with the development of automated assembly lines, surface mount technology (SMT), and increased miniaturization, leading to the current era of high-density, multi-layered printed circuit boards (PCBs) and sophisticated semiconductor fabrication.

Key Components of Electronic Design

Electronic design encompasses several critical stages, starting from conceptualization to detailed design implementation. The initial phase involves ideation and requirement analysis, where the purpose and specifications of the electronic device are defined. Following this, designers use specialized software tools like CAD and electronic design automation (EDA) for creating detailed circuit diagrams and layout designs.

Prototyping plays a vital role, often using breadboards or simulation software to test and refine the designs. This phase ensures functionality, efficiency, and adherence to design specifications before moving into mass production. Additionally, the design process must consider factors like component availability, cost-effectiveness, and compliance with industry standards to ensure a successful and viable product.

Manufacturing Processes

Electronic manufacturing transforms design blueprints into tangible products, involving several intricate processes. It begins with PCB fabrication (https://conclusive.tech/services/pcb-design/), where multiple layers of conductive and insulating materials are combined to form the board. Advanced manufacturing techniques like SMT are employed to mount and solder components onto the PCB. This method has largely replaced the traditional through-hole technology, allowing for smaller, more compact devices.

Quality control is a critical component of the manufacturing process. It involves thorough testing for functionality, reliability, and compliance with standards. Techniques like Automated Optical Inspection (AOI) and X-ray inspection are commonly used for detecting manufacturing defects. Final assembly often involves integrating the PCB into a larger system, along with other mechanical and electrical components.

The manufacturing process is not without its challenges, often involving intricate supply chain management to ensure timely availability of components. Additionally, the increasing complexity of electronic devices demands precision and miniaturization, pushing the boundaries of current manufacturing capabilities. The drive towards sustainability also requires manufacturers to adopt environmentally friendly practices and materials, further complicating the process.

Challenges in Electronic Design and Manufacturing

One of the major challenges in electronic design is keeping pace with rapid technological advancements. Designers must continuously update their skills and knowledge, adapting to new tools and technologies. Balancing innovation with cost-effectiveness and manufacturability is also a significant challenge, particularly for smaller companies.

In manufacturing, the complexity of modern electronic devices presents numerous challenges. Precision assembly, quality control, and ensuring the reliability of increasingly miniature components are ongoing concerns. Additionally, supply chain disruptions, often caused by geopolitical issues or global events, can significantly impact production schedules and costs.

Environmental and sustainability concerns are also increasingly prominent. The electronics industry faces pressure to reduce its carbon footprint, manage electronic waste, and use sustainable materials. Adhering to these environmental standards while maintaining profitability and efficiency is a complex balancing act for many manufacturers.

Future Trends and Innovations

The future of electronic design and manufacturing is poised for groundbreaking innovations. Artificial intelligence (AI) and machine learning are expected to play significant roles in automating and optimizing design processes, predicting failures, and enhancing manufacturing efficiency. The Internet of Things (IoT) will continue to drive demand for smarter, more interconnected devices.

In manufacturing, trends like 3D printing and advanced robotics are set to revolutionize production processes, enabling more customization and flexibility. The push for sustainability is likely to lead to the development of more eco-friendly materials and energy-efficient manufacturing practices.

Additionally, advancements in semiconductor technology, such as the development of quantum computing and nanotechnology, promise to redefine the capabilities of electronic devices. These innovations will not only enhance performance but also open new horizons in various fields, from healthcare to space exploration.

Conclusion

In conclusion, electronic design and manufacturing are dynamic fields characterized by continuous evolution and innovation. They play a pivotal role in shaping the technological landscape, influencing everything from consumer electronics to industrial systems. While the industry faces significant challenges, particularly in terms of technological complexity and environmental sustainability, it also stands on the brink of exciting advancements. The future of electronic design and manufacturing is undoubtedly bright, with immense potential for innovation and growth, promising to deliver more advanced, efficient, and sustainable electronic solutions for the next generation.

Leave a Reply